**We all know the saying: blood, sweat, and tears. That’s exactly went into Troy Gayton’s 2008 Jeep Wrangler JK. He built his ideal rig on his own (yes, seriously). It took him 3.5 years and nearly 800 hours, but piece-by-piece his build came together. We had the pleasure of sitting down with Troy this week and learning all about what went into building his Jeep really looked like. If you’re like us (and we’re guessing you are), you’re going to enjoy this one. **

How did you get into off-roading and the Jeep Scene?

I’ve pretty much always been into off-roading my whole life. I was born and raised in Alaska, off-roading up there with full-sized rigs. And once I graduated college, I was visiting my parents in New Hampshire and my dad introduced me to a young kid who he worked with at a heavy equipment operation back in the day. This guy had just recently went to tech school at a place called WyoTech and I was blown away at his ability to come into the room and solve a complex problem in like 15-20 minutes. He almost served as an inspiration for me to go to tech school and told me that if I was even considering going, that I should just do it–that I’d discover my passion there. And sure enough, a few months later, I ended up going to WyoTech myself.

I spent almost 10 months in Laramie, Wyoming and once I got into my Chassis Fabrication course, it all just clicked. I fell in love. I ended up graduating as one of the top kids in that class and then my Chassis Fabrication instructor was so moved by how I could work with metal, he had me work on his own personal vehicle.

And from there, I left Wyoming and ended up in Denver. From that class on, I always remained intrigued and wanted to grow my skills. We learned suspension design from the ground up so I just kind of fell into it. Then, I bought a 2007 4-door Rubicon used and just started goofing around on it. And then over the years, it just kind of happened. All of the sudden, everything I learned in school became applicable to this vehicle and I thought: “Shoot, I can do this myself, I don’t need to pay anyone.” I started screwing around with metal and the suspension and it all just started coming back to me. I started to remember all the things I learned in school and I basically built this 4-door Jeep up back in the day when forums were the thing, and then I sold it (my girlfriend thought I was nuts).

That’s when I had a vision of what I wanted to build from the ground up. So I found the Jeep I wanted (a 2008 Jeep Wrangler JK X) and that’s when this build officially took off.

What was the build process like?

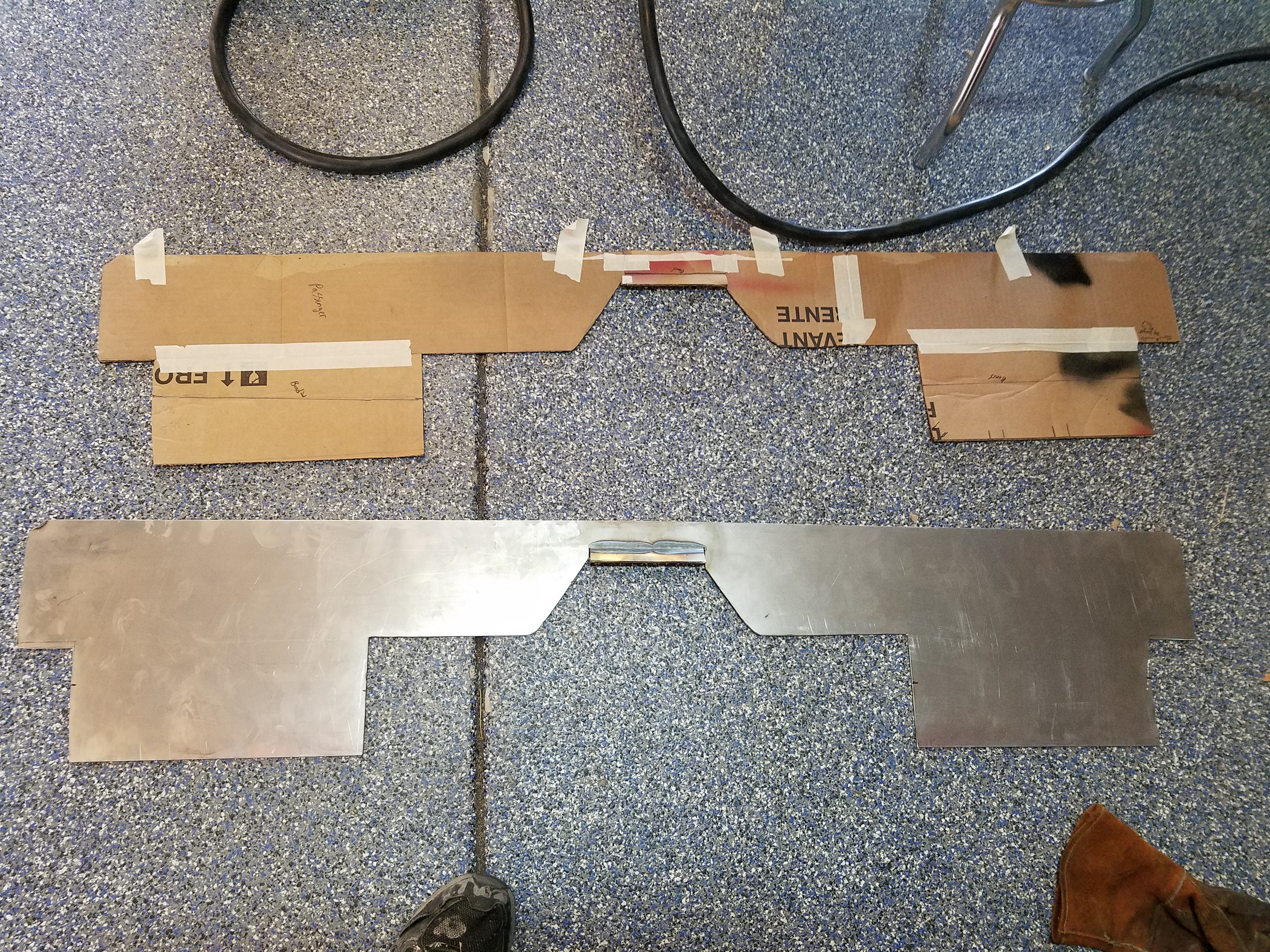

The Jeep I bought had no A/C, roll-up windows…it was just a bone stock, street tire 2-door that I purchased from a dealership, but I had big plans to build it from the ground up (my girlfriend thought it was the ugliest thing in the world). I don’t have much CAD or computer design experience so when it came time to take the build on, I basically did it all in my head.

I drove the Jeep for about a year before making any modifications. And finally on January 1st, I decided it was time…time to park it and tear it apart. So I did that and a week later, I had the body off the frame. From there, I cut the frame in half and started thinking about the suspension design I planned to do and that’s when I was like “I don’t even need the rear frame for this, it’s not going to work for what I want to do.” And that’s when my brain took over and I decided to take everything I had been thinking about since tech school and make it happen for this Jeep. My way.

I didn’t want to copy anyone, I just wanted to do everything I thought should be in MY Jeep. And that’s what I did. The build took about 3.5 years. Nearly 800 hours.

I had a little bit of a delay (8 months to be exact) due to a company I decided to have help me with some customization. Eventually, after the work wasn’t getting done the way it should have been, I just took it back and finished it myself.

After reworking some of the front end work that had been done, it was time to focus on the rear end. I wasn’t going to have any repeat mistakes. For an entire year, I was on my build every spare second I had. Before work. After work. I’d stay up until 2am. People just didn’t understand. Everyone would ask me “what are you doing in there?” In which I would reply “what do you think I’m doing?!” I even canceled my cable so that I could focus all my energy on the build. My girlfriend even thought I was cheating on her at one point and came over to my house late at night to see if I was home…and sure enough I was out in my garage plugging away.

I did have a bit of help though. I needed help press braking 1/4″ steel. The Flop Shop hand-built my rear 1/4″ steel body/armor around my cage. They also built/mounted my fuel cell and my 1/4″ steel boat side rockers.

People would often ask me what my motivation was, or how I could be so dedicated to finishing the build (when other Jeep owners and friends I had had given up on their builds) and my answer was always “I just see the end result in my head. And I see me on the trail with my rig.”

What’s your favorite part of the build?

The funnest part of the whole thing is the cage. It took me the longest to build too.

It’s inspired by my time in tech school. When I was in school in my Chassis Fabrication class, me and my class partner would roll through our list of assignments as quickly as we could so that we could get to the extra stuff. One of the extra projects we did was build bumpers out of tubed DOM that matched my classmate’s Nerf bars. We bent it around his rear bumper and around the sides of the body. We also integrated a hitch that dropped 17 inches with heim joints that went up to the frame for more support. We built this crazy thing, got it done and then once class was over, took it over to his garage and painted it all the match his side rails. And when we brought it to class at the end of the year, the Dean of WyoTech, himself, came out and couldn’t believe what we had built.

The significance of that, is that messing around and screwing up a bit in school taught me a lot of skills and tricks that I may not have learned had I not worked through screw ups like this one. The cage on my Jeep took the longest to build, as I said and it’s because of the attention to detail I gave that thing.

If you look at the cage directly from the side, I tried to make both the harness bar and the shock hoop the same angle so that no one may notice that directly, but your eyes just naturally follow both of those lines. From every angle of the Jeep, there are certain aspects I made a very specific way so that it followed the vision I had in my head. People don’t really notice that stuff until I point it out, but that’s how you can see the attention to detail of the rig.

The one thing I really thought a lot about before I built the cage was that I wanted it to be removable. It basically took me 3 months of just headache, trying to figure out stuff. But now, if I want to I can remove the entire dash/body portion. I can just unbolt it and remove it all from the Jeep. I basically built it like a puzzle so that the pieces fit perfectly together and can be changed pretty easily.

What’s different about the suspension?

I looked at a lot of the RC world and they all seemed to build these things that are super low but just have big tires. I’d watch them crawl all over the rocks, almost like a little spider and I always thought it looked really cool. They don’t flip over that easy either.

I also looked at the Jeep and off-road world and these crazy krawlers like the single seat buggies (ex: Jesse Haines Fabrication Moon Buggy) and how these things just don’t unload on the suspension and that’s when I decided I’m going to build a full-bodied JK (which is wider than any other style of Jeep) and I’m going to lower it and make it look like a hot rod. So I built it so low because I want the whole weight of this rig in between the axles. And although I knew it was going to make for a great off-roader, I knew it was going to be a pain in the ass to learn how to drive. People don’t necessarily understand that. When I’m driving it and people see it in person, they realize how low it really is. Lots of people tell me it looks like an RC car, and I’m like “yeah, that’s the point.”

And of course there are some haters out there that just think I’m showing off. And actually if I was to hit an obstacle the same way a normal rig does, I would completely turtle out. Every time.

I hit obstacles so screwed up, my fear of rolling over sideways is pretty much nonexistent. Even when it feels like we might roll over, we just keep crawling and walk out of it.

Being as low as it is (2.25 inches lower than factory to be exact) is an adjustment to say the least. In fact, I even put my truck tires on it once to compare and it was so low to the ground that you could barely get yourself underneath it. It almost looked like an oversized golf cart. You could lean over and your gut would touch the top of the half door.

What was the biggest challenge?

I just went for it. Everyone basically told me I was nuts. People would come over to my garage, see what I was doing and see that I was just covered in metal dust and basically looking like a scrub. I had a lot of people who questioned me or would ask how I knew what I was doing and I would always just take things one step at a time. My motivation was out of control. I mean I’d be lying if there weren’t times where I had to take a week off because I was just so overwhelmed. I’d have to basically avoid the garage for a week or so to let my brain shut off for a bit. But even through all of that, it was fun.

It was SO much fun to build. And I never got to a point where it was a burden. When other people I knew gave up, I never did.

What’s your favorite place you’ve taken it off-roading?

Of course there’s Moab, and it’s fun and everything, but I’ve done it for years. And now I’ll even go as far to say that Moab is boring. The trails are limited and you have to stay the trail (which I get it).

I went up to South Dakota this year with my Jeep and I had a blast. We hit buggy lines and stuff, and even though we didn’t get into the super serious trails (because they were closed), we were able to walk a lot of it to see what they had to offer.

I’ve been all over Colorado and I would say one of my favorite places that I’ve ever been is Sand Hollow in Utah. Hands down, anyone who ever goes there will probably never wheel Moab again.

It’s BLM. You can stay on the trails but you don’t have to. So there aren’t any limitations on where you can drive there so you can veer off and climb over trees, rocks, everything…it doesn’t matter.

What’s up next for you and your build?

I just recently went to Moab for Krawl America and filmed our time out there. We were out there with Crawl 5280 and we got to capture a ton of great video and photos. (Huge shoutout to Crawl 5280 for helping me to capture great photography of my build). I had a big sponsor in my group and I got to take them out, it was really cool. Everyone seemed to be pretty intrigued by my Jeep…like everyone would just stop, go quiet and stare at my build. It was actually kind of weird. And then they’d see me crawl some crazy line and everyone seemed to be amazed. It was a cool feeling.

By the end of the weekend, I was chatting with Gabe, the owner of Aerolidz (they make covers for any size/width LED light bars) and he was commenting on my rig and was adamant that we needed to do something together. So as we were talking, I expressed an interest in going to SEMA in November. I had plans to go last year, but it got canceled. He told me he had a booth at SEMA.

Next thing you know, my Jeep will be in his booth at SEMA next month. In fact, it’s the only rig in his booth. So he’s basically going to tailor the entire booth around my Jeep, which is just so exciting.

We also linked up about Artec Industries (who I’ve dealt with a lot, I’ve got a lot of their parts that I’ve modified on my Jeep). They said we could use a pedestal for the show. So they are going to bring a 36-inch pedestal to the show, and we’re going to put the rear of my Jeep on it. One tire on the rear so it’ll stretch the Jeep out. It’s kind of like a bucket list thing for me.

So are you as amazed as we are at this thing? The amount of time and detail put into 4 Play shows. Big things are on the horizon for Troy and his completely custom build. We’re excited to see what the future has in store for this rig and we’ll be sure to keep you in the know as this thing crawls all over the US. Be sure to show some love to his build and this article if you’re into this masterpiece.